Understanding the Valve System of an Engine: Function, Types, and Maintenance

- Quality Auto & Body

- 24 jul 2024

- 5 Min. de lectura

The valve system in an internal combustion engine is crucial for its efficient operation. It acts as a "gate" that regulates the flow of the air-fuel mixture into the cylinders and the expulsion of exhaust gases. In this note, we will explore in-depth the engine's valve system, including its function, various types, and the importance of maintenance to ensure optimal engine performance.

The valve system in an internal combustion engine is essential for the intake and exhaust cycle. It consists of several valves that open and close in synchrony with the piston’s movement. This system allows the air-fuel mixture to enter the cylinder during the intake phase and enables exhaust gases to exit during the exhaust phase.

1.1 Importance of the Valve System

Without a proper valve system, the engine could not operate correctly. Efficient intake and exhaust of the air-fuel mixture and exhaust gases are crucial for maintaining performance, fuel economy, and emissions within permissible limits. A well-designed and maintained valve system ensures that the engine operates efficiently and extends its lifespan.

2. Types of Valves

Various types of valves are used in engines, each with its own characteristics and functions.

2.1 Intake Valves

Intake valves allow the air-fuel mixture to enter the cylinder. These valves must open at the right time to allow the cylinder to fill with the mixture needed for combustion.

2.2 Exhaust Valves

Exhaust valves are responsible for releasing exhaust gases from the cylinder after combustion. Like intake valves, they must open at the right time to prevent residual gases from staying in the cylinder, which could affect engine efficiency.

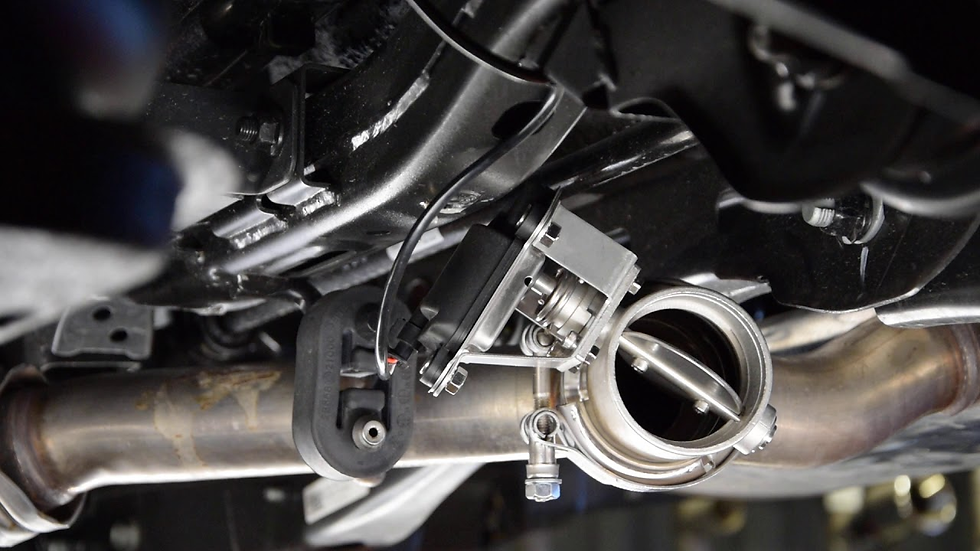

2.3 Gate Valves

Gate valves, also known as throttle valves, are used in older engines and some industrial applications. These valves regulate the flow of air or fuel and can be manual or automatic.

2.4 Variable Valve Timing

In modern engines, variable valve timing valves are used to optimize engine performance at different speeds and loads. These valves adjust their opening and closing based on engine operating conditions, improving fuel efficiency and reducing emissions.

3. Operation of the Valve System

The operation of the valve system is synchronized with the piston’s movement through the camshaft. The camshaft is a crucial component that controls the opening and closing of the valves.

3.1 Intake Cycle

During the intake cycle, the camshaft opens the intake valve to allow the air-fuel mixture into the cylinder. This valve remains open while the piston descends, creating a vacuum that draws the mixture into the cylinder.

3.2 Compression Cycle

Once the intake valve closes, the piston ascends to compress the air-fuel mixture in the cylinder. This process increases the pressure and temperature of the mixture, preparing it for combustion.

3.3 Combustion Cycle

The compressed mixture is ignited by a spark (in gasoline engines) or by compression (in diesel engines), causing combustion. The resulting pressure pushes the piston down, generating the power needed to move the vehicle.

3.4 Exhaust Cycle

After combustion, the exhaust valve opens to allow the exhaust gases to exit the cylinder. The piston ascends again to expel the residual gases, preparing the cylinder for the next intake cycle.

4. Types of Valve Systems

There are various valve system configurations and designs, each with its own advantages and disadvantages.

4.1 Overhead Valve (OHV) System

In the overhead valve (OHV) system, the camshaft is located in the engine block and operates the valves through pushrods and rocker arms. This design is older but still used in some engines due to its simplicity and durability.

4.2 Double Overhead Camshaft (DOHC) System

The double overhead camshaft (DOHC) system features two camshafts in the cylinder head, one for intake valves and one for exhaust valves. This design allows for more precise valve control and better air-fuel mixture distribution.

4.3 Single Overhead Camshaft (SOHC) System

The single overhead camshaft (SOHC) system has one camshaft in the cylinder head that controls both intake and exhaust valves. This design is less complex than DOHC but offers less precision in valve control.

4.4 Variable Valve Timing System

The variable valve timing system adjusts the opening and closing of the valves based on engine conditions. This technology enhances performance across different speed and load ranges, optimizing fuel efficiency and reducing emissions.

5. Maintenance of the Valve System

Proper maintenance of the valve system is essential to ensure engine performance and longevity. Here are some recommended maintenance practices.

5.1 Valve Clearance Check and Adjustment

Valves should be checked and adjusted periodically to ensure they operate correctly. Adjusting the valve clearances involves setting the proper gap between the valves and the camshaft. Incorrect adjustment can lead to power loss, increased fuel consumption, and higher emissions.

5.2 Camshaft Inspection

The camshaft should be inspected regularly for wear or damage. A damaged camshaft can affect engine performance and cause valve system failures.

5.3 Replacement of Worn Components

Components of the valve system, such as valves, rocker arms, and pushrods, should be replaced if they show signs of wear or damage. Timely replacement of these components ensures efficient operation and extends engine life.

5.4 Use of Proper Engine Oil

Engine oil plays a crucial role in lubricating the valve system. Using the recommended type and amount of oil helps reduce wear and friction in the valve system, keeping it operating smoothly and efficiently.

6. Common Valve System Problems

Several common problems can affect the valve system. Here are some of the most frequent issues and their possible solutions.

6.1 Valve Wear

Valve wear can cause power loss, increased fuel consumption, and higher emissions. Wear can result from inadequate lubrication, incorrect adjustment, or residue buildup in the engine.

Solution: Replace worn valves and adjust the valve system according to the manufacturer’s specifications.

6.2 Compression Leaks

Compression leaks can occur if the valves do not seal properly, leading to power loss and reduced efficiency. Leaks can be caused by valve wear or damage to the valve seats.

Solution: Inspect and replace valves and valve seats as necessary to ensure proper sealing.

6.3 Camshaft Misalignment

Camshaft misalignment can affect valve system timing, leading to performance issues and operational problems. Misalignment can be caused by incorrect installation or component wear.

Solution: Adjust and align the camshaft according to the manufacturer’s specifications to ensure precise timing.

6.4 Variable Valve Timing Issues

Variable valve timing systems can experience issues if sensors or adjustment mechanisms fail. These problems can affect engine performance and efficiency.

Solution: Diagnose and repair or replace faulty sensors or mechanisms to restore proper variable valve timing function.

Conclusion

The valve system in an internal combustion engine plays a critical role in its overall performance and efficiency. Understanding its function, types, and maintenance requirements is essential for ensuring optimal engine operation and longevity. Regular inspections, timely replacements, and proper maintenance practices are crucial to keeping the valve system in top condition. By addressing common issues and adhering to maintenance guidelines, you can ensure your engine performs efficiently and reliably for years to come.

Comentarios